Introduction:

Soldering machines are essential elements for a wide variety of industries, ranging from electronics manufacturing to jewelry making. They play an important role in connecting two or more components with solder metal, which is a kind of filler that melts to join two or more items. In this article we shall explore the functionalities and applications of soldering machines that make them indispensable in different sectors.

Types of Soldering Machines:

There are several available types of soldering machines that come in the market specifically suited to individual needs and uses. Hand-held solder irons, solder stations and reflow ovens are among the common examples. Small projects can easily be performed using portable handheld solder irons. More temperature controls are provided by the solder stations and they also come with additional features like adjustable power settings and digital displays. Reflow ovens are large scale production tools as they handle numerous components all at once.

Key Features:

The ability of a solder machine to sustain constant temperatures is one of its most critical aspects. This ensures that the solder melts symmetrically and consequently forms strong bonds between the components. Many modern type’s also have adjustable power settings enabling individuals to control heat output according to their needs. Others have advanced safety configurations including auto shut off systems or overheat protection.

Applications:

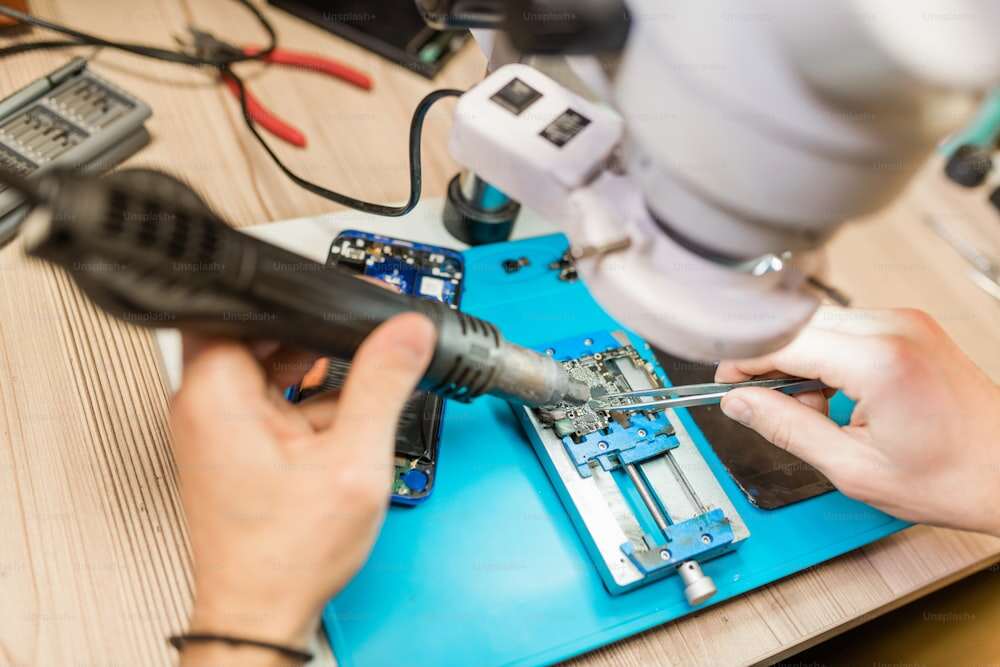

Soldering devices find use within various sectors where there is need for accuracy as well as dependability.. In assembling circuit boards for electronics industry, resistors; capacitors as well as integrated circuits must be linked together using these apparatuses.. Jewelers also depend on these mechanisms when joining metallic parts to create unique shapes and designs on them.. Also used in automobile manufacture for wiring harnesses et cetera.

Maintenance Tips:

To enhance your device performance as well as extend its lifespan you should carry out proper maintenance procedures on your solders’ machine. Regular cleaning using a damp sponge or brass wire brush on the tip helps minimize build-up and improve heat transfer. When not in use, it is advisable to keep your machine in a dry place so as to avoid any moisture damage. Regular inspections and replacements of worn parts will go a long way towards ensuring that the machine remains fully functional.

Conclusion:

Soldering machines are flexible tools for different industries. They allow experts to achieve reliable results when performing tasks like circuit board assembly and jewelry making due to their ability to provide accurate temperature levels and control them too. You can get the best out of soldering machines through understanding diverse kinds that exist as well as following proper maintenance techniques. Being a hobbyist or expert, getting an efficient soldering machine will boost your output in projects thereby enhancing productivity and success levels.

Hot News

Hot News